Quality Camlock Coupling: Ensuring Safety and Efficiency in Liquid Transfer

Camlock couplings are pivotal in many industries, facilitating a swift and secure connection in liquid transfer systems. Their quality must be emphasized, especially when safety and efficiency are paramount. This article delves deep into the essence of camlock couplings, their importance in liquid transfers, and the consequences of compromising on their quality.

Table of Contents

Toggle1. Understanding Camlock Coupling: The Basics

What is a Camlock Coupling?

Camlock couplings, also known as cam and groove couplings, allow for quick and easy connection and disconnection of hose fittings. These couplings are designed for convenience and ensure a leak-proof connection, ideal for transferring liquids, gases, and dry products.

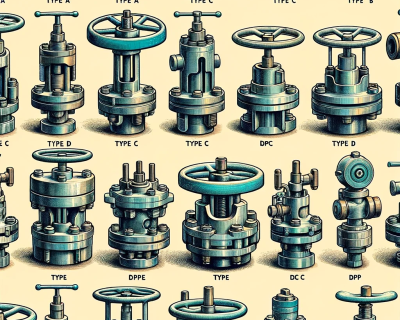

Different Types of Camlock Couplings Available

- Type A: Male adapter with a female thread

- Type B: Female coupler with a male thread

- Type C: Female coupler with a hose shank

- Type D: Female coupler with a female thread

Common Materials Used in Production

The choice of material for camlock couplings depends on their application. Some commonly used materials include:

- Aluminum: Lightweight and corrosion-resistant, ideal for water and hydraulic applications.

- Stainless Steel: Known for durability and resistance to high temperatures, perfect for food, chemical, and pharmaceutical industries.

- Brass: Resistant to rust and suitable for high temperatures, often used in manufacturing and industrial applications.

How Camlock Couplings Function

The efficiency of camlock couplings is due to their simple mechanism. They function by pushing the grooved coupling into the cam coupling and then closing the levers. The cam arms’ pressure on the groove ensures a tight, leak-proof connection, eliminating the need for tools or clamps.

2. The Importance of Quality in Camlock Couplings

Direct Correlation Between Quality and Safety

The quality of camlock couplings directly influences the safety of the liquid transfer process. High-quality couplings ensure a secure connection, reducing the risk of leaks and spills, which can lead to accidents, environmental hazards, and financial losses.

Ensuring Longevity and Durability with Quality Materials

Investing in quality camlock couplings guarantees durability and Longevity. High-quality materials resist wear and tear, corrosion, and temperature-induced damage, ensuring the collars last longer and require fewer replacements.

The Cost Implications of Choosing Low-Quality Couplings

While low-quality couplings might seem cost-effective initially, they often lead to frequent replacements and potential liquid transfer failures. Such incidents result in direct financial losses due to equipment damage and operational downtimes and harm the company’s reputation.

3. Safety Concerns in Liquid Transfer

Potential Risks in Liquid Transfer Processes

Liquid transfer, if not done correctly, can pose several risks, such as:

- Chemical spills leading to environmental hazards

- Potential fire or explosion in the transfer of flammable liquids

- Product contamination in the food and pharmaceutical sectors

Role of Camlock Couplings in Mitigating These Risks

Quality camlock couplings are the frontline defense against these risks. By providing a secure connection, they prevent unwanted disconnections and spills, thereby ensuring the safety of both the personnel and the environment.

Case Study: An Incident Involving Subpar Couplings

In 2018, a manufacturing plant faced significant losses due to a chemical spill resulting from a failed camlock connection. The incident was traced back to a substandard camlock coupling that emphasized the need for investing in quality equipment.

4. Efficiency Boosters: Benefits of Quality Camlock Couplings

Quicker Connection and Disconnection

Quality camlock couplings are designed for quick and easy connections, saving time and reducing labor costs.

Minimal Spillage Leading to Reduced Waste

With high-quality camlock couplings, the risk of disconnections and subsequent spillages is minimal, reducing product waste and enhancing operational efficiency.

Less Wear and Tear, Leading to Fewer Replacements and Downtimes

Camlock couplings of robust materials withstand regular use, aggressive chemicals, and high temperatures. This durability means fewer replacements, less downtime, and uninterrupted operations.

Quality camlock couplings are indispensable in ensuring the safety and efficiency of liquid transfer processes. Investing in high-quality equipment guarantees operational success and safeguards the environment and personnel. As industries continue to expand and evolve, quality camlock couplings will remain paramount, making them an essential aspect of modern-day operations.

5. Standards and Certifications: Ensuring Camlock Quality

Introduction to Industry Standards for Camlock Couplings

The industry has recognized the importance of camlock couplings and, as such, has implemented rigorous standards to maintain their quality. Institutions like ISO (International Organization for Standardization) and ASTM (American Society for Testing and Materials) set these guidelines, ensuring that the couplings are designed and manufactured to meet specific minimum safety requirements.

How to Identify Certified Quality Camlock Couplings

Identifying genuine, high-quality camlock couplings involves:

- Checking for certification markings or stamps on the product.

- Verifying product details and certifications with the manufacturer.

- Referring to the product’s datasheet, which should provide details about its build, materials, and certifications.

Importance of Purchasing from Reputable Manufacturers and Suppliers

Buying from reputable sources ensures you invest in quality products that comply with industry standards. Established manufacturers invest in research, utilize advanced manufacturing techniques, and adhere to quality control measures, all of which contribute to the production of superior camlock couplings.

6. Maintenance and Best Practices

Regular Inspection Routines for Camlock Couplings

Like all equipment, camlock couplings require regular inspections to guarantee their effectiveness and Longevity. Inspections should check for:

- Wear and tear, especially in the locking arms and gaskets.

- Corrosion, especially if used in aggressive environments.

- Proper sealing to prevent leaks.

Cleaning and Maintenance Tips to Extend Longevity

To maximize the lifespan of your camlock couplings, consider the following maintenance tips:

- Clean the couplings regularly using suitable cleaning agents, especially after transferring aggressive or sticky liquids.

- Replace worn-out gaskets promptly.

- Lubricate the moving parts occasionally to ensure smooth operations.

When and How to Replace Camlock Couplings for Optimum Safety

Camlock couplings don’t last forever. It’s crucial to recognize when they need replacement. Signs include:

- Visible signs of wear and tear or corrosion.

- Frequent leaks, even after gasket replacements.

- Difficulty in connecting or disconnecting the couplings.

When replacing, always ensure the system is depressurized and follow the manufacturer’s guidelines for proper installation.

7. Innovations in Quality Camlock Coupling

Advances in Material Science Enhancing Camlock Coupling Quality

Continuous research in material science has brought forward newer alloys and materials that offer better corrosion resistance, higher temperature thresholds, and enhanced durability for Camlock couplings. The aim is to make them more adaptable to challenging environments and versatile across industries.

Innovative Design Features That Enhance Safety and Efficiency

Modern camlock couplings come with innovative features like:

- Improved locking mechanisms for faster and more secure connections.

- Color-coded handles for easy identification of liquid types.

- RFID chips for tracking and maintenance scheduling.

Looking into the Future: What’s Next for Camlock Couplings?

With the increasing integration of IoT in industries, the future may see smart camlock couplings that can self-diagnose wear and tear, communicate maintenance schedules, or even auto-adjust based on the liquid being transferred.

The emphasis on the quality of camlock couplings highlights their indispensable role in various industries. Industries can ensure safer, more efficient operations by understanding their functioning, recognizing the importance of quality, and adhering to maintenance best practices. As innovations continue to revolutionize this space, camlock couplings will undoubtedly adapt, becoming even more integral to liquid transfer processes in the future.